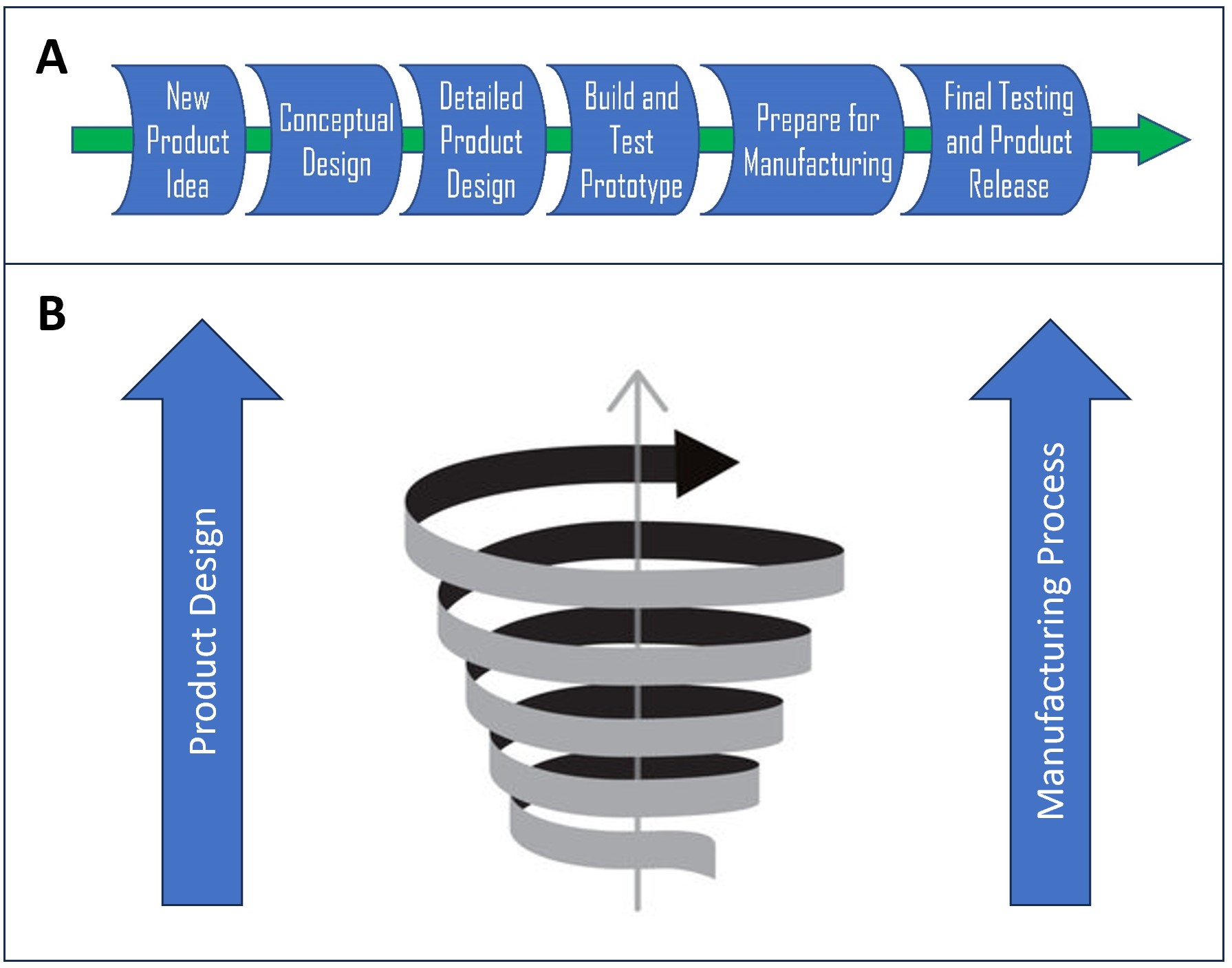

I like using an upwardly spiraling approach to product design and development. The first loop of the spiral includes rough information about the market size, target customers, and customer needs; conceptual design options that could be potential solutions to the technical challenges; examination of possible manufacturing processes that could be used to make the custom components, possible purchased components, and a basic strategy to manufacture the complete product; project management issues including an initial estimate of the total product cost, investment required, and the timeline; and a brief consideration for all other aspects of product viability such as sales distribution channels, intellectual property barriers/opportunities, regulatory requirements, end user engagement, etc. During each loop of the spiral, aspects of the product will begin to solidify as more details are developed. Using a parallel approach keeps one aspect of the project from getting too far ahead of others without consideration of the “big picture”. Today, most companies use some type of parallel product development process. However, start-up companies, university researchers, and companies that have not adapted to modern methods, may use a more linear process.

Design Engineer: This is one of the three common roles performed by engineers in a corporate setting. Often, they are divided by discipline, mechanical, electrical, and software, but in smaller companies, design engineers will take on interdisciplinary functions. Mechanical design engineers are responsible for creating the product design using 3D CAD modeling. Features are included in the design to meet product performance specifications. Some parts are custom, and others are purchased. All are modeled to create an assembly model of the entire product. Tolerances are assigned based on manufacturing process capabilities, and the fit requirements based on how the parts interact. For low volume products like those for aerospace/defense applications, the technical challenge is often simply getting the product to function reliably. In high volume products, a key element is establishing proper part tolerances to ensure that natural variability in part dimensions do not produce problems in manufacturability, line yield, or product performance. Cost must also be controlled in high volume manufacturing. A ten cent (USD 0.10) difference on a high-volume product like a truck that sells 1,000,000 units per year equates to $100,000 each year. Over a typical automotive production life cycle, this equates to $500,000. So, clearly it is worth spending the engineering time to optimize the product design for this magnitude of benefit. When the analysis becomes too laborious for hand calculations, computational modeling and simulation tools like finite element analysis (FEA), computational fluid dynamics (CFD), and custom mathematical models (MATLAB/Python) can be used to optimize the design. Design engineers also need to ensure that the design still functions over the entire range of temperatures and environmental conditions over which it is rated. In addition, it must meet product life requirements and be safe for public use. These are some of the concerns addressed by mechanical design engineers. Electrical and software design engineers perform similar activities in their disciplines. Overall, design engineers must design and develop a product that meets or exceeds performance requirements (based on customer needs) and does this reliably at a reasonable cost.

Manufacturing Engineer: This is the second of three common roles performed by engineers in a corporate setting. It may be divided by discipline (mechanical or electrical), but there is often overlap with manufacturing engineers doing both. Manufacturing engineers design equipment to manufacture the products created by the design engineers. This may include an automatic welding machine designed specifically for the product being manufactured, bowl feeders to deliver parts in a specific orientation, automated assembly equipment to place an o-ring on a shaft, or an end of line tester to verify product performance before packaging and shipping. As an example, consider an ultrasonic welder used to seal the edges of a remote keyless entry device. The manufacturing engineer must understand the product requirements for sealing the device and ultrasonic welding technology. Using this information the manufacturing engineer would search for commercially available devices that could be used as the foundation of the machine (it is much more expensive to build a custom machine when one is available for purchase). Custom “horns” would be designed to match the specific part being manufactured. For medium to high volume products, this machine would be dedicated to making only the one product and the equipment set-up on the production line. Next the manufacturing engineer would program the machine to perform the needed operation and optimize the performance through a multitude of test parts until it was capable of completing the manufacturing operation at high performance and yield. This process would be done for all the operations needed to build the product. Generally, it is arranged in a U-shaped production line with material flowing in from the start of the line and the outside, and finished parts being packed for shipping at the end. Manufacturing engineers also need to consider the people working on the line to ensure that a safe work environment is created with hazards being eliminated or at least minimized. Manufacturing process steps are documented along with machine settings for consistent results. When the product changes, the equipment to manufacture it may also need to change. Overall, manufacturing engineers design, build, and maintain the production manufacturing equipment and create the processes needed to manufacture commercial products.

Quality Engineer: This is the third of three common roles performed by engineers in a corporate setting. Quality engineers monitor the quality of the products being manufactured to ensure that they meet requirements set by the company. Not all aspects of the product design can be measured through inspection (i.e., long term life testing), but if a part fails to meet dimensional checks it may be an indication that there is a problem. For general products, a few critical dimensions (those important to product performance) are checked to verify that the dimension of the part is within the tolerance range (typically +/- some value). In addition to verifying that the parts pass, the actual measurement is usually tracked to see if the mean drifts. While parts may still be passing (e.g., usable products that meet specifications), if the reason for the drift is not addressed, it could result in parts being manufactured that are out of specification in the future. For simple parts this role may be performed by a quality assurance technician. More complex parts may require advanced methods to ensure quality. This may include nondestructive testing (ultrasound, x-ray, etc.) to search for interior cracks or occlusion not visible from the surface of the part. Quality engineers also create and maintain the quality system (ISO 9000, cGMP, etc.), ensuring that equipment is calibrated, track manufactured parts (if necessary), etc.

Project Manager: This function may be performed by a design, manufacturing, or quality engineer already working on the project, or by a dedicated project manager. Project managers coordinate the activities of the development team, develop and track timing plans (Gantt charts), and track cost. They typically are the same level as the engineers that they work with, managing the “project” not the “people”. This can make the role of project manager challenging. However, project management can also be quite rewarding because project managers are involved with every aspect of the project providing them with a better understanding of the product, not just one aspect.

Consultants: Smaller companies often find it less costly to hire consultants to do work that may not be needed regularly. This may include hiring accountants only during tax time. Other roles also commonly hired as consultants include attorneys, regulatory consultants, marketing consultants, engineering strategists, etc. As the company grows, consultants can be replaced by full-time staff. For technical companies, some of the first people added as a company grows include a director of business/finance and a director of engineering.